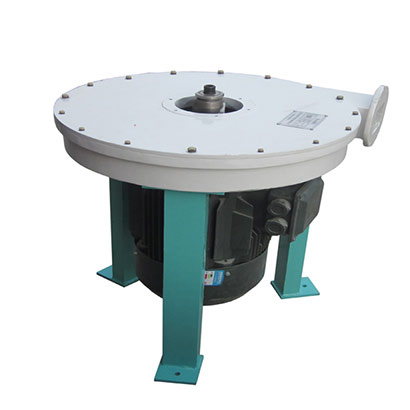

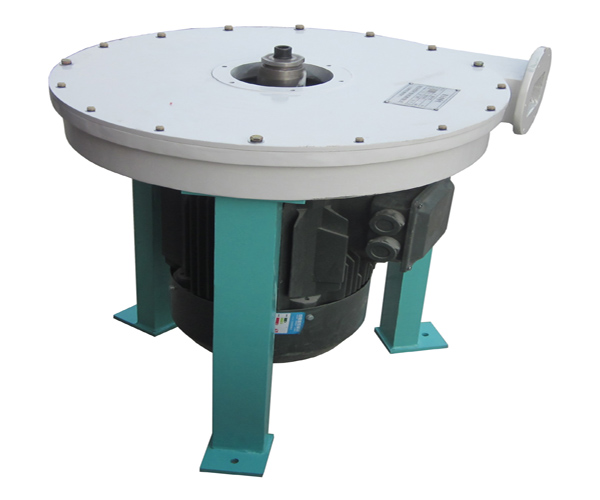

Impact Mill

The FMFZ series impact mill is a commonly seen device in flour manufacturing plants. It is used to shatter grains after they have received reduction grinding so as to enhance the flour yield rate and alleviate the burden of roller mills. For example, after the first or the second pass of reduction grinding is completed, this product could be applied, and the flour yield rate can reach up to 30%-40%. Aside from this application, this machine is also suitable for metallurgy, food processing, medicine production, electronic product and other fields.

Features of Impact Mill:

1. Optimized Grinding Process

Due to the high-speed impact, the fine particle content is increased. Under some circumstances, this impact mill is able to serve as a piece of stand-alone equipment to finish a certain grinding step, and this will save corresponding cost.

2. Precise Control of Particle Size Distribution

The VFD motor could control the speed of impact, and this means the impacting effect is accurately adjusted. As a result, the particle size distribution is precisely controlled.

3. Low Running Cost

The machine components are fabricated through casting process, and they are extremely robust. So, our machine exhibits excellent wear-resistance, prolonged life span as well as highly ensured operational reliability, thereby cutting down the running cost to a large extent.

Technical parameter of Impact Mill:

|

Model |

Throughput (t/h) |

Power (kW) |

Overall dimensions (L×W×H, mm) |

|

FMFZ45 |

0.5-0.7 |

5.5-7.5 |

605×580×630 |

|

FMFZ53 |

1-1.5 |

11-15 |

680×660×700 |

Ethiopia MEJER Flour Factory PLC.

Ethiopia MEJER Flour Factory PLC. ordered our 40T/Day Wheat Milling Plant